Reality Checks for Assembly BOMs

Currently, during the processing of an assembly order, users can manually adjust the quantities of components or assembly quantity/ actual yield. This flexibility can result in discrepancies between the consumed quantities and the final outputs, leading to inaccurate inventory movements and potential stock issues. To address this, we propose the implementation of a setting/ toggle that restricts adjustments to assembly quantities once an order is authorized, ensuring that the output aligns with the BOM specifications.

For clarification to the above, these are some examples,

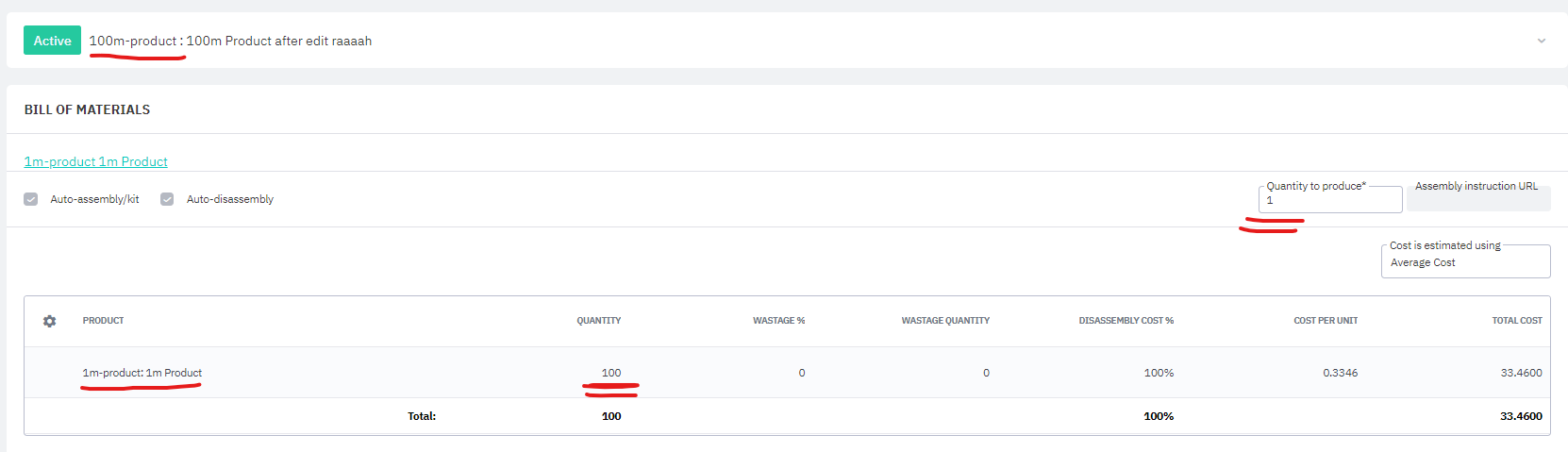

1 unit of SKU 100m-product = 100 units of SKU 1m-product

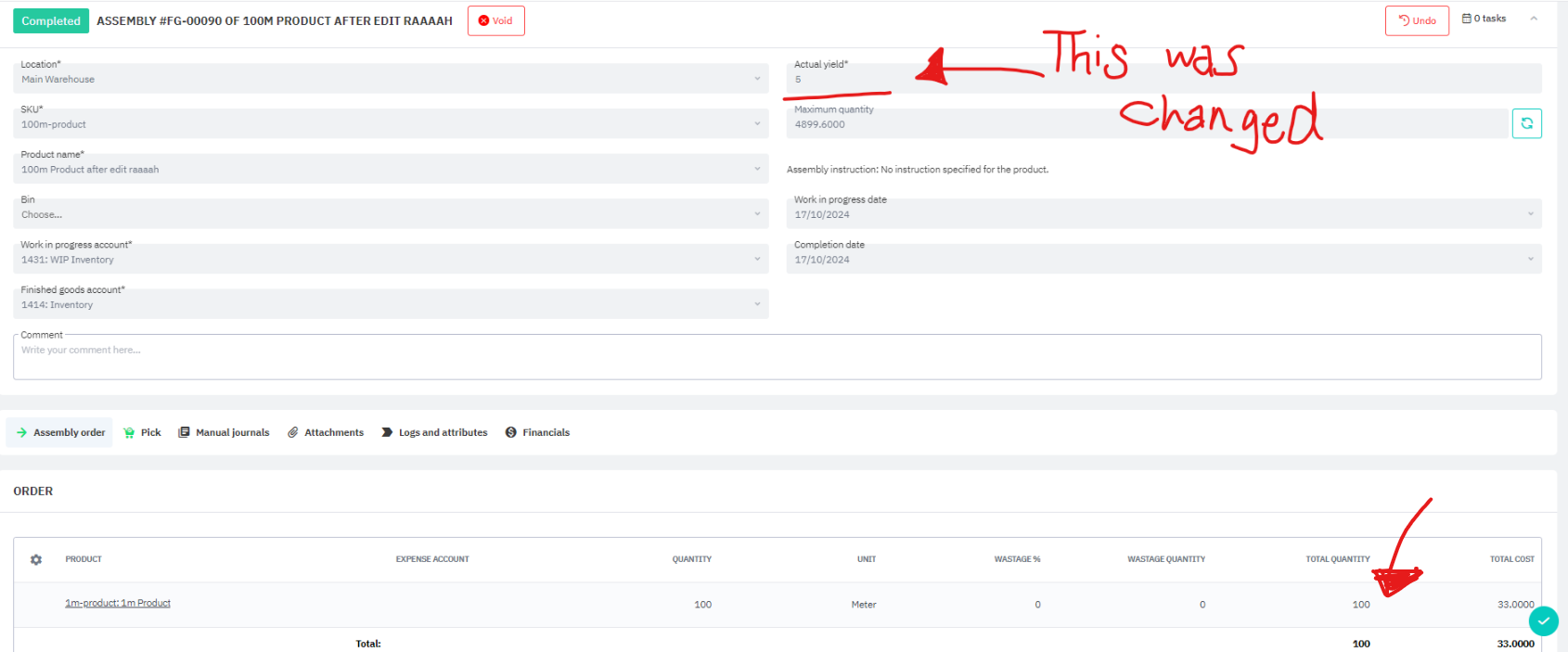

FG-00090 was initially processed for 1 unit of 100m-product (100 units of 1m-product), but after authorising the assembly order, it is possible to change the actual yield, meaning that the output does not tally to that of the consumed components, as per the BOM.

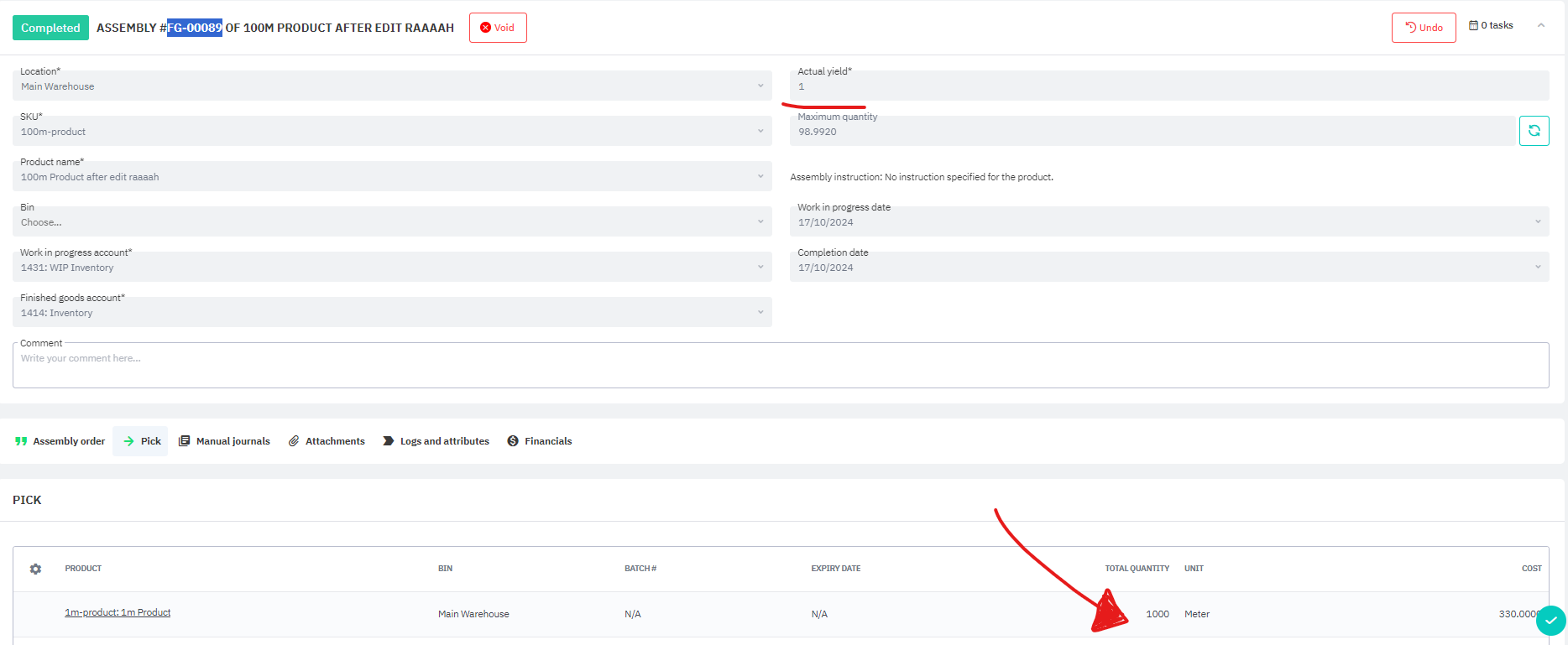

FG-00089 was processed for 1 unit of 100m-product—the assembly order was authorised, but in the pick stage, it is possible to change the pick quantity, again leading to the output not tallying with the consumed components, as per the BOM.

Implementing this prevents adjustments to assembly quantities and pick quantities after authorization, and would be vital for ensuring accurate inventory management and alignment with BOM specifications.

Please consider this enhancement for the upcoming product roadmap to help users maintain consistency and accuracy during the assembly process.

Related to

Comments

1 comment

Yes, this is causing countless problems on our stock so would really appreciate it if a check can be built in to stop users from over utilizing raw material when assembling.

Please sign in to leave a comment.